News

VAR-SPE K2 SERIES VAR-SPE SERIE K2 with easy handwheel control for serie HDA chemical injection pump, ensure a minimal chance of failure. Turning the rate adjustment dial of the variator counterclockwise will increase the pump stroke rate. In this type of pumps the variator has been preset to limit rotation to a single direction. This ensures the pump will stroke at its minimum rate with the variator dial in the full clockwise position. The variator control knob can be adjusted while the unit is off without damage to the unit.

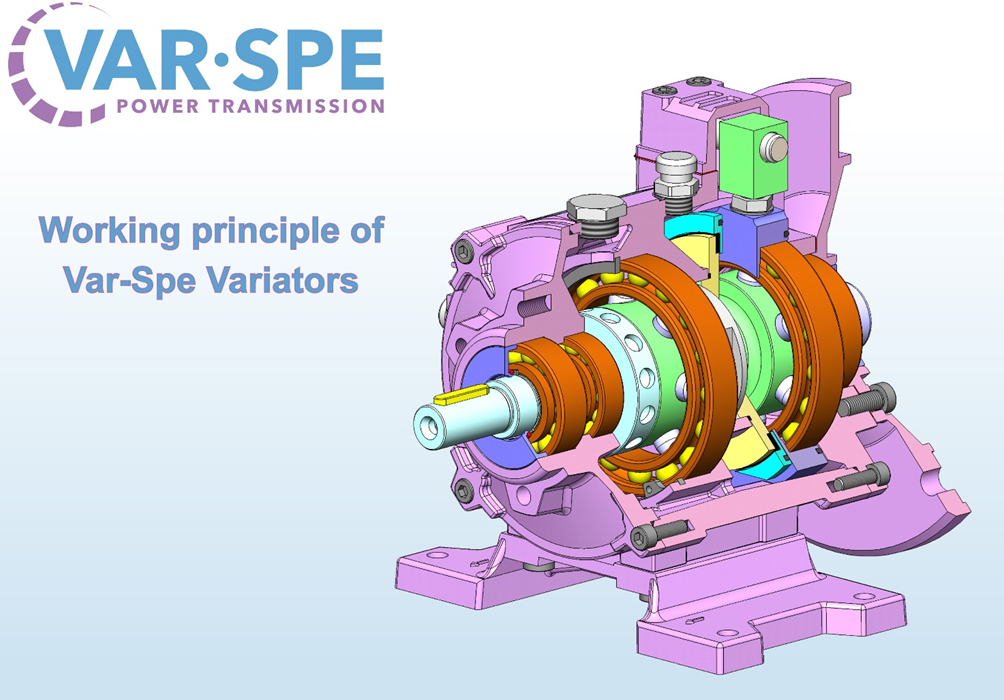

HOW IS THE DIFFERENCE BETWEEN HYDRAULIC SPEED VARIATOR AND MECHANICAL VARIATOR? VAR-SPE HYDRAULIC SPEED VARIATORS Many customers ask to us which are the differences between hydraulic and mechanical variator: we thought to create a summary sheet with the main characteristics. VARSPE VARIATORS: Working Principle Var-Spe Hydraulic speed variator has a main circuit composed by primary and secondary pumps. Both units are housed in the same case, and they are mounted on a fixed distributor shaft. Speed regulation is accomplished by adjusting the eccentricity of the primary pump and, therefore, the oil flow is sent to the secondary pump (with fixed eccentricity). The latter, connected to the output shaft, drives a speed that is directly proportional to the received oil flow.So, the max eccentricity of primary pump corresponds to the max speed rotation of output shaft, smaller eccentricity will correspond to a lower output speed rotation. (see Image Nr. 2) MECHANICAL VARIATOR : Working Principle The mechanical variable speed transmission system is based on the transfer of power, by friction, beetween a moving part (moved by the control speed), drive and driven shafts. THE TWO VARIATORS CHANGE THE SPEED IN TWO DIFFERENT WAY BUT OUR VARIATORS HAS THESE ADVANTAGES: EASY MAINTENANCE: the fully lubricated circuit creates an oil film that PRESERVES from wearing down all internal components, the minimal MAINTENANCE is the replacement of the oil that allows A VERY VERY LONG LIFE of the hydraulic variator, internally the components have No MECHANICAL STRESS ..NO FRICTION SAFETY of Varspe variators: each VARIATOR is equipped with safety valves that are involved in case of the blocking of the machine… basically in case of stop the valves allow the discharge of oil into the variator case SPEED CONTROLS: we have a very different range of speed controls: handwheel, pneumatic, electric, lever, ELETTROTRONIC. We can customize the VARIATORS acc. to the customer’s requests, depending on the application, type of environment, etc. VARSPE covers the power till 22 KW HEAVY SERIES (generally Mechanical Variator arrives to max 9,2 KW) WIDE RANGE OF SPEED : speed range from 0 to 1500 / 1750 RPM FAST INVERSION IN BOTH SENSES OF ROTATION Possibility to adjust the speed also with el. motor switched OFF FINALLY… OUR VARIATOR IS THE ONLY VARIATOR THAT HAS THIS TYPE OF WORKING PRINCIPLE.